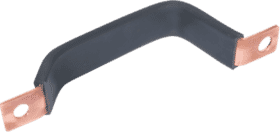

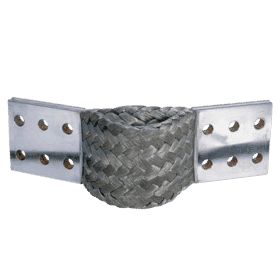

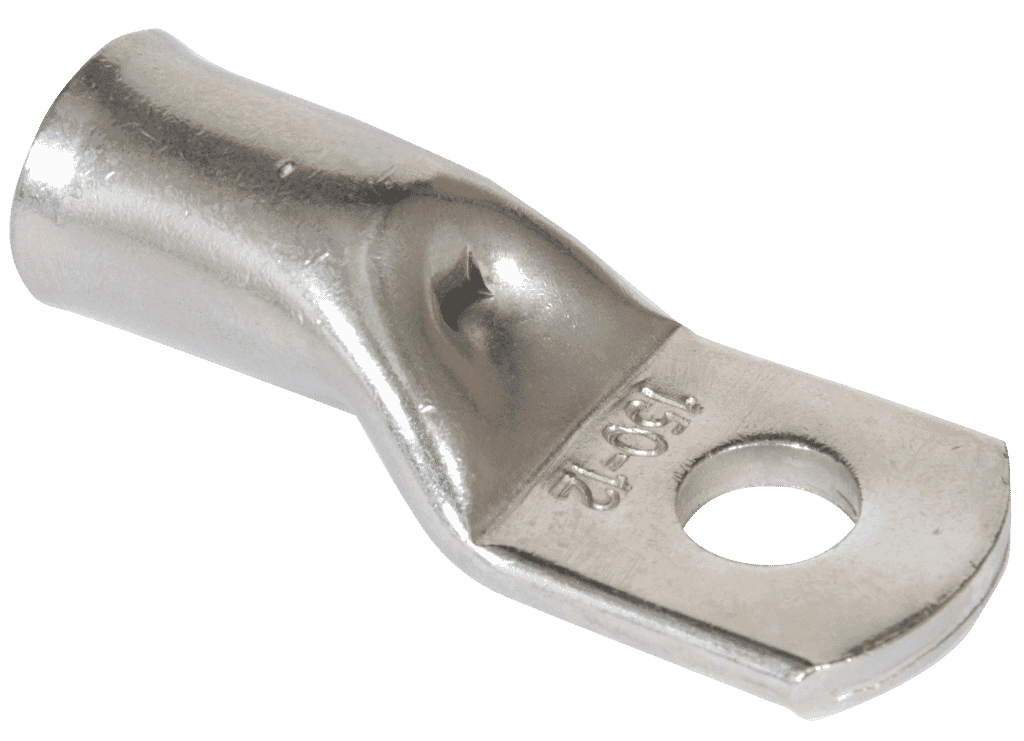

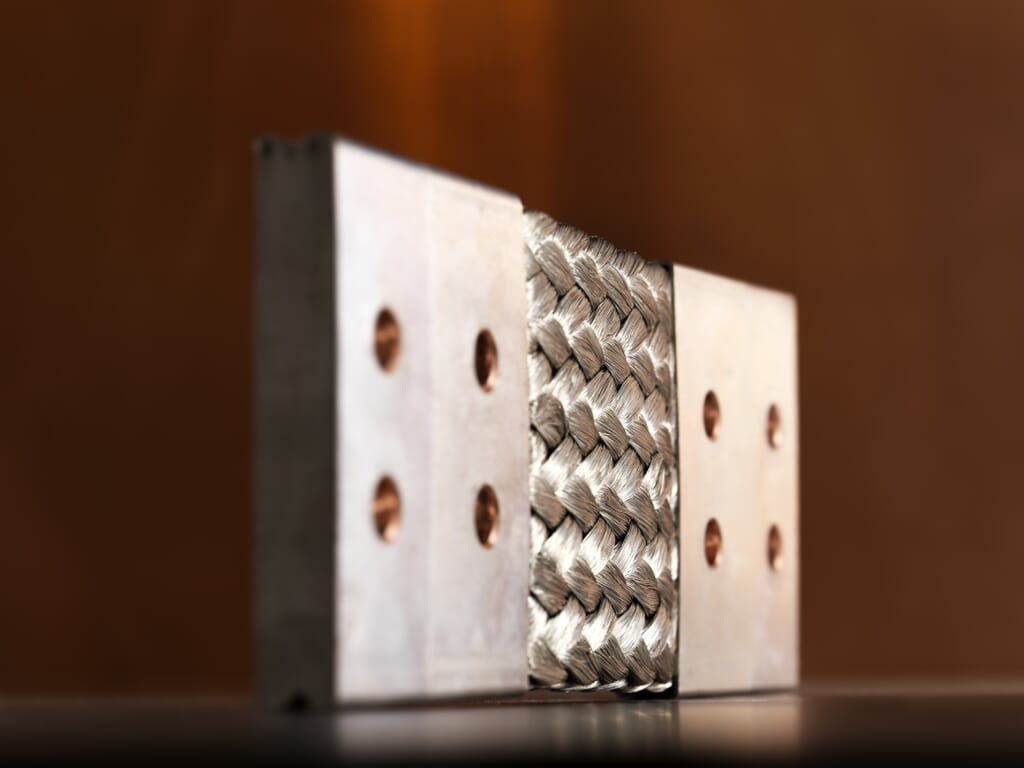

LML Manufactures Copper tube terminals, spliced connectors for cable installations, heavy-duty busbars, custom-designed copper bar work

Custom Quality Electrical Components Production

Trust LML to support you with proactive design, precision manufacturing, tailored finishing, testing and after-sales care.

Proud to have partnered.

Products Range

Make an enquiry

LML Products is the most trusted supplier of busbar, cable, connector & earth bar in the UK. We’re ready to talk about your project.

Or Call: 01249 810000

Electrical Cable Terminations from LML Products

Established since 1968, LML Products manufactures copper-tube terminals from 10-1000mm^2, along with many other high-current components, at its own facilities…

Read More

Temperature Impact of Insulation applied to Electrical Conductors

Executive Summary Heat loss from a surface in contact with air depends on the temperature difference between the surface and…

Read More

Outline thermal behaviour of metallic conductors

Executive Summary Faraday asserted the economic optimum of a conductor with balanced costs of resistive dissipation and finance. This is…

Read More