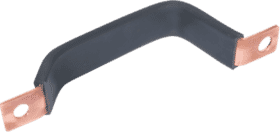

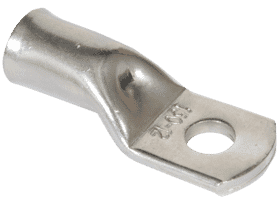

CABLE TERMINATIONS

Standard copper-tube lugs and bespoke terminals

Price and quality application-optimised; rapid delivery for standard products.

Benefits of our copper tube terminals & electrical lugs:

- LML manufactures a standard range of copper-tube terminals for cable-sections from 10mm2 to 1,000mm2 using premium mill-produced copper for optimal DC resistance & thermal stability.

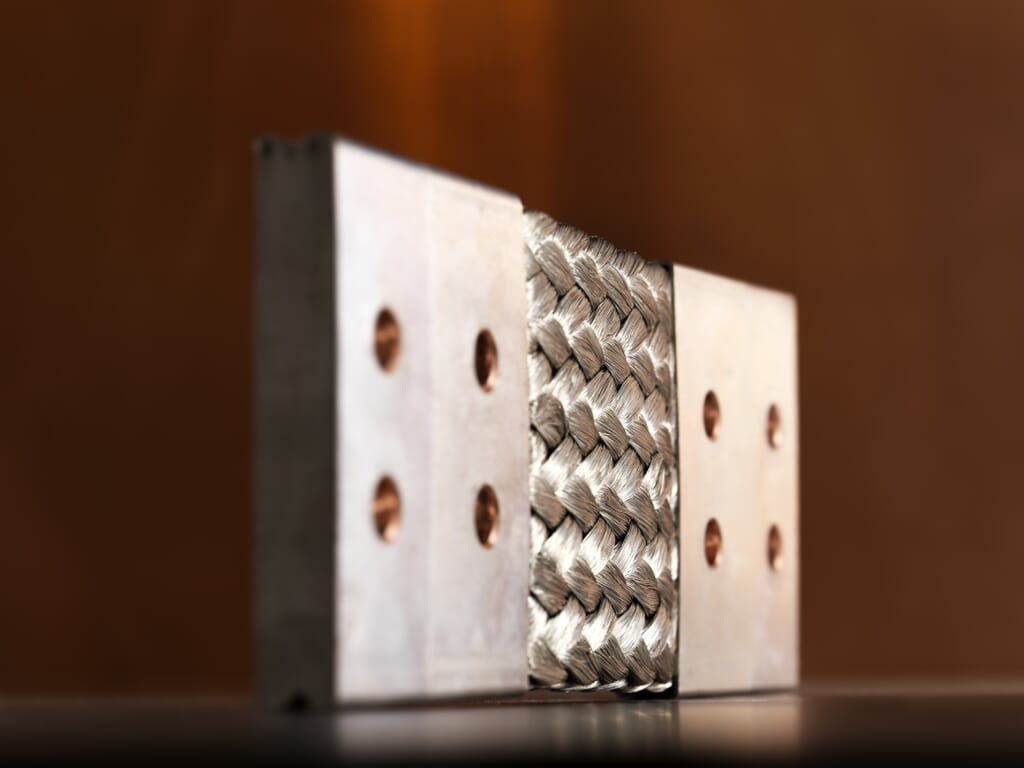

- Custom terminations and pins can be formed from tube or machined from solid with extended brazed palms if required.

- Copper cross-section, crimping requirement, specialised contact palms or pins, hermetic sealing, plated finish plus many other features can be supplied to your specification.

- Sample batches or volume production to suit your needs.

- Technical & design support, including numerical modelling and testing

- Comprehensive manufacturing, detailing and finishing processes with renowned quality standards

- UK manufacture ensures reliable rapid deliveries

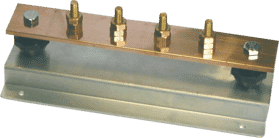

Custom copper tube terminals

LML Products has the expertise and facilities to manufacture custom copper tube terminals for the most demanding projects. Discover more about our standard and bespoke products by clicking the photo opposite.

Make an enquiry

LML Products is the most trusted supplier of busbar, cable, connector & earth bar in the UK. We’re ready to talk about your project.

Or Call: 01249 810000